">

">

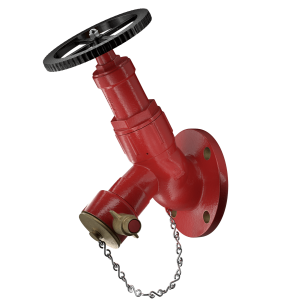

PRV9i – The FM approved, 9 bar interchangeable pressure regulating valve.

Designed and manufactured in-house in our UK facility, the PRV9i is made for uses in critical oil, marine, gas, construction, defence and petrochemical applications.

It offers the end user great flexibility both in operation and maintenance, with an interchangeable cartridge system and a variety of available configurations that are all FM approved to ensure the highest levels of safety.

Suited for use with fire hose connections, stations, standpoints as well as fire pump headers on high pressure systems, the PRV9i is perfectly engineered to regulate pressure in fire protection applications. The PRV9i further meets all performance criteria necessary for 1.5″ and 2.5″ valves for various hose connections and offers excellent corrosion resistance in harsh environments.

| FM TESTED AND APPROVED |

| A pressure regulating valve for use with fire hose connections |

| Used on hose connections, hose stations, and fire pump headers on high pressure systems |

| For flow rates up to 250 GPM

3rd Party Witnessed by Lloyds (Report Ref: PRJ11100245070) |

| Meets all performance criteria necessary for 1 ½″ and 2 ½″ valves for hose connections for hose stations, standpoints, and fire pump headers |

Expertly manufactured for certification compliance and traceability, the PRV9i series is highly accredited and certified. Each valve is rigorously analysed and pressure tested for compliance and quality before leaving our UK factory, ensuring a valve that is both robust and reliable.

Building a market leader

Walter Frank launched the PRV9i range in 2008, which has been leading the market on quality, approval and performance ever since. The PRV9i range has been specified for use in a number of prestigious projects such as Heathrow Airport (UK), the Wheatstone offshore project (Australia), the ADNOC Offshore UZ750 project (UAE), the Crossrail London Underground project (UK) and most recently the Long Son Petrochemicals Complex project (Vietnam).

Due to its interchangeable cartridge system, the PRV9i benefits from quicker and easier servicing as well as less down time on the system, resulting in a reduced ‘through life’ cost and making it a popular choice.

UK Made and Quality Assured

The design, casting, machining and assembly plus full flow testing and calibration for the PRV9i are all performed in-house at our production facility in the UK.

Trust and reliability are absolute fundamentals for such large-scale infrastructure projects and safety-critical environments, which is why the PRV9i is strongly tested, certified and accredited.

Prior to pouring, all furnace melts are spectrographically analysed for compliance, while valves are pressure tested and each given a unique serial number to ensure that it has passed all requirements. The PRV9i exceeds the requirements of British firefighting Standard BS9990 for interchangeability and performance, is FM approved and also ISO9001:2015 accredited.

The choice for national and international projects

The compliance with both national and international standards puts the PRV9i at the forefront of pressure regulating equipment.

With the ability to be certified by independent bodies including Factory Mutual (FM) & Lloyds, the PRV9i is an excellent choice for fire-protection systems in demanding environments where such compliances are a necessity.

As a trusted supplier, we have been responsible for providing permanently charged wet barrel pillars for the ADNOC Offshore Upper Zakum Offshore Oilfield Development project in the UAE, as well as bespoke hydrant assemblies for the tunnel sections in London’s Crossrail project.

The PRV9i also offers a complete solution for offshore environments, where it has been specified for projects that have involved the outfitting, refurbishment and maintenance of offshore platforms.

Flexible and responsive

We collaborate with our customers to design and engineer bespoke solutions to meet all needs, including advising on the use of corrosion-resistant materials for demanding environments.

Our UK-based and well-resourced casting, machining and assembly platforms means that we offer impressive lead times as well as high quality products.

For more information on our PRV9i series, please download a product datasheet or catalogue here: