">

">

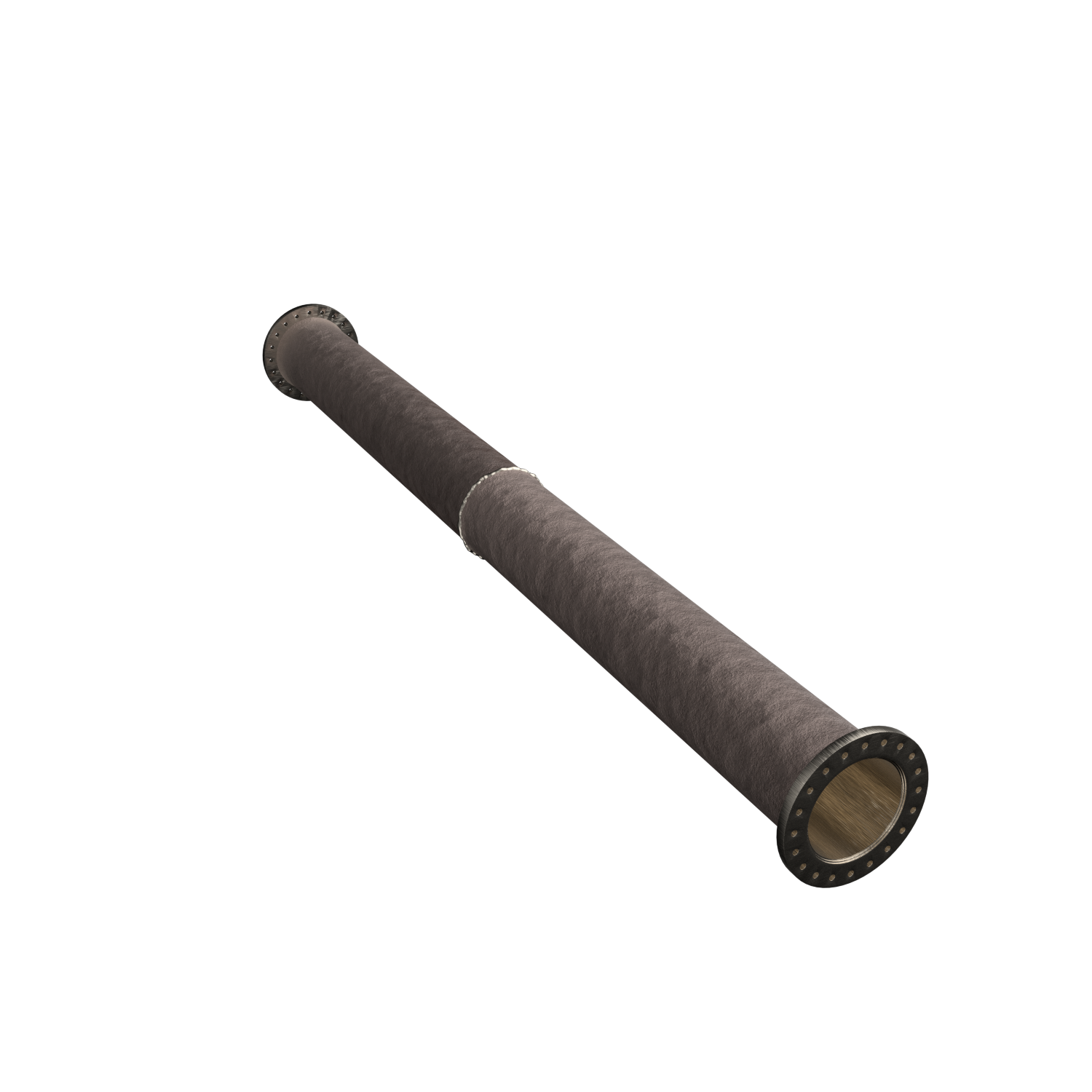

The full integration of centrifugal casting, sand casting, machining and fabrication enables Spunalloys to specialise in these bespoke and highly engineered assemblies for the offshore industry for use with vertical firefighting pumps. Our horizontal centrifugal casting process has the advantage of producing tubes with an integrally cast flange, which means that only one centre butt weld is required to create one pipe assembly rather than three with other production methods. This has cost, time, and structural integrity advantages.

All column pipes / riser mains are radiographed, finish-machined, assembled, third party inspected and tested for onward shipment to the customer’s client. Castings and fabrications are fully traceable to individual heat number cast, and certified to customer requirements. Spunalloys has supplied column pipes in copper based and steel alloys to the pump industry world-wide for over 25 years. Literally thousands of column pipes and riser main assemblies have been supplied to pump makers in Europe, the USA, India and Australia, and installed all over the world.