Spunalloys is the UK’s largest, most diverse non-ferrous and ferrous centrifugal castings foundry. Rings, tubes and special shapes are offered either proof or finish machined, fully tested, certified and assembled as required. Our world-leading range of heat, wear and corrosion resistant materials includes copper, nickel, steel and other exotic materials. We engineer safety critical products for naval and marine propulsion shaft liners, column pipe/riser mains for offshore vertical pumps, environmentally critical wellhead products for the oil & gas industries, and special alloys for the aerospace turbine industry.

Westley Group launches new Corporate Social Responsibility (CSR) strategy. Committing ourselves to creating sustainable value for stakeholders while delivering robust economic performance.

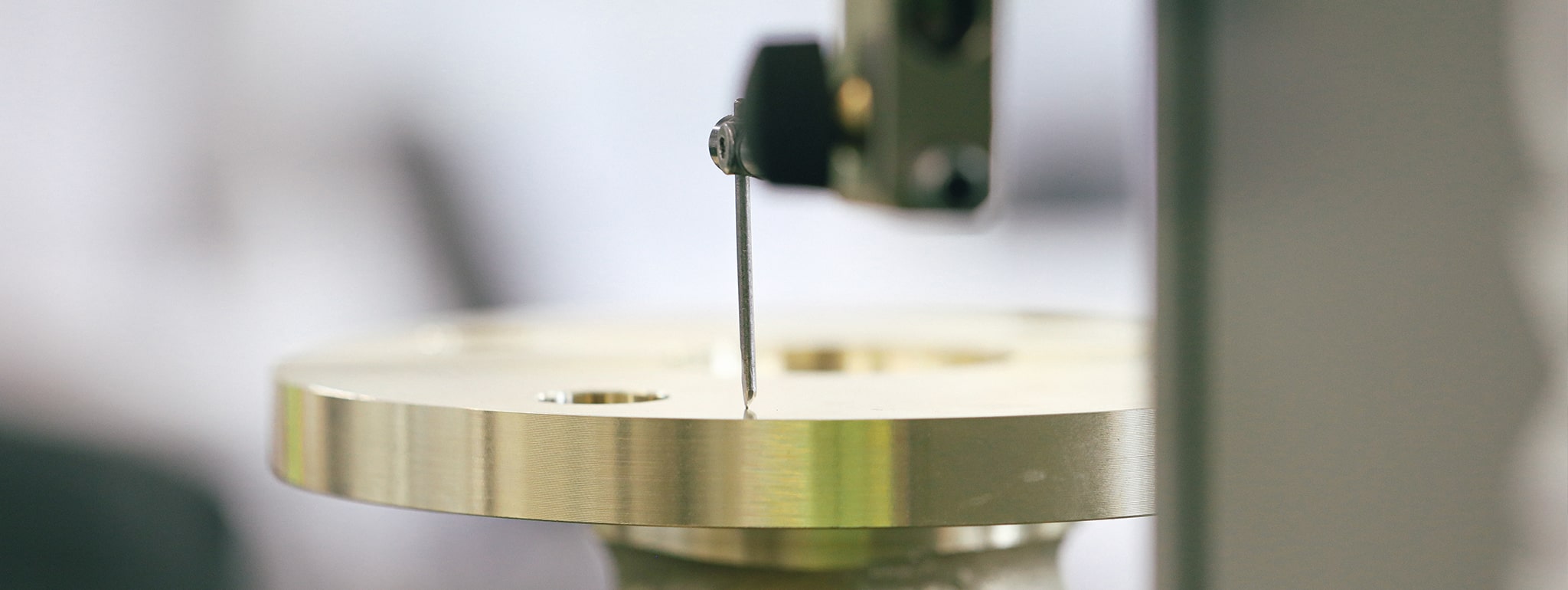

We’ve invested in state-of-the-art Zeis and Axiom CNC CMM assets and software that enhance our delivery of industry-leading precision products.

As affiliated members of the US Naval Submarine League, we attended their 40th NAVSEA symposium, where we held discussions with US primes and the US Navy.

The UK, Europe, the Middle East, USA: over the past 12 months, we’ve taken part in trade exhibitions and conferences.

Westley Group launches new web site and corporate image.

Medium FARO arm inspection installed at Francis Birketts and Walter Frank

New investment for Spunalloys Finish Machine Shop, with large Doosan DBC130 CNC horizontal borer, and Doosan Mynx 9500 milling machine with fourth axis

Ravensburg Centre Lathe 8000 mm capacity installed at Spunalloys

Spunalloys formalises aerospace approval to AS9100

Centrifugal liner procedures approved by NAVSEA USA

Further centrifugal investment for Spunalloys, with new 5m-length spinning machine

Formation of Meighs & Westleys. Creation of the finalised sand casting centre of excellence, with consolidated sand casting activities.

Large FARO arm inspection machine installed at Cradley Heath

SC21 Continuous Sustainable Improvement Plan commenced with Babcock as primary sponsor. Group metrics standardised in line with the programme

Investment in St Peg Lane including new lathes and Haas VF6 and VF4 machining centres

Aquisition of J Roberts Bronze site and relocation of FWB and Walter Frank from Hightown Road site to improved site layout on St Peg Lane

Acquisition of Meighs Castings and Campbell Road site

Francis Birketts installs new suite of LMSA CNC lathes

Walter Frank gains FM Approval for PRV9i

Creation of a dedicated centre of excellence for centrifugal casting, with further investment in Cradley Heath foundry to broaden Spunalloys’ centrifugal machines and furnaces

Creation of a dedicated centre of excellence for static sand casting, with consolidation of Westleys Ltd sand casting operation on Holditch Road site

Consolidation of FWB and Walter Frank bronze foundry activities on Holditch Road, with new semi-automatic carousel and dedicated furnace room

Remodelling of Holditch Road site’s production and support layout to prepare for growth

Trent Foundries relocated and consolidated alongside J.T. Price on the Holditch Road site

Walter Frank designs and launches PRV9i

New electric induction furnaces installed at Meighs & Westleys creating 14,000 kgs of melting capacity

Westley Group acquires Sweetmore Engineering Holdings (renamed J.T. Price)

Founder member of the UK Foundry Industry Health and Safety Initiative SHIFT

Walter Frank relocated to Cleckheaton and consolidated alongside sister company FWB

Westley Group acquires Walter Frank & Sons Ltd

James and Rob Salisbury create Musgrave Holdings

Westley Group is a specialist UK partner for high integrity castings and tight tolerance machining. Trusted experts in heat, wear and corrosion resistant alloys for a wide range of safety critical applications, customers depend on our unrivalled experience in delivering cast and finish machined components.

The unique, vertically integrated manufacturing capability of our static and centrifugal foundries and machine shops, gives full control and flexibility over all aspects of manufacture and supply – enabling us to delivery industry leading performance metrics.