Our Aerospace Experience

Westley Group supplies a number of aerospace components from different manufacturing cells.

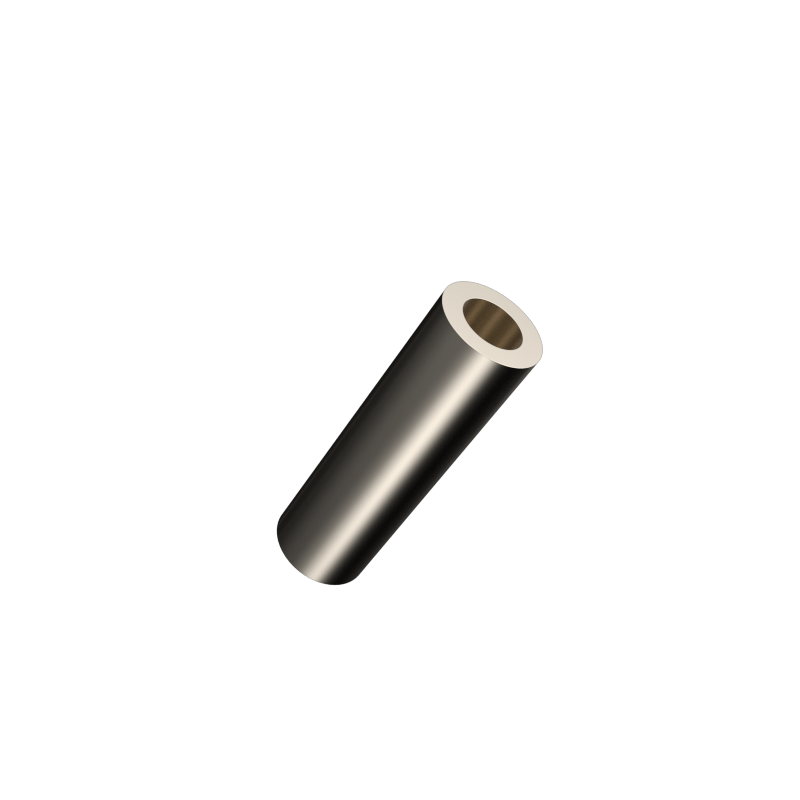

Supporting the industry for many years, we have both an AS9100 and Rolls Royce SABRE approval for the supply of MSRR material in Trent engine components. MSRR material is very reactive, but our stringent furnace and pouring techniques control this within the high speed horizontal centrifugal casting process. All of the components are heat treated and dye penetrant checked against the strictest defect parameters.

It is increasingly uncommon for large static castings to be required for aerospace applications. The Group however still supports the industry and regularly produces the machine gun turret housing for fast jets such as the Typhoon. These sand castings are produced in defect-free nickel aluminium bronze and have to pass exacting NDT processes prior to machining.

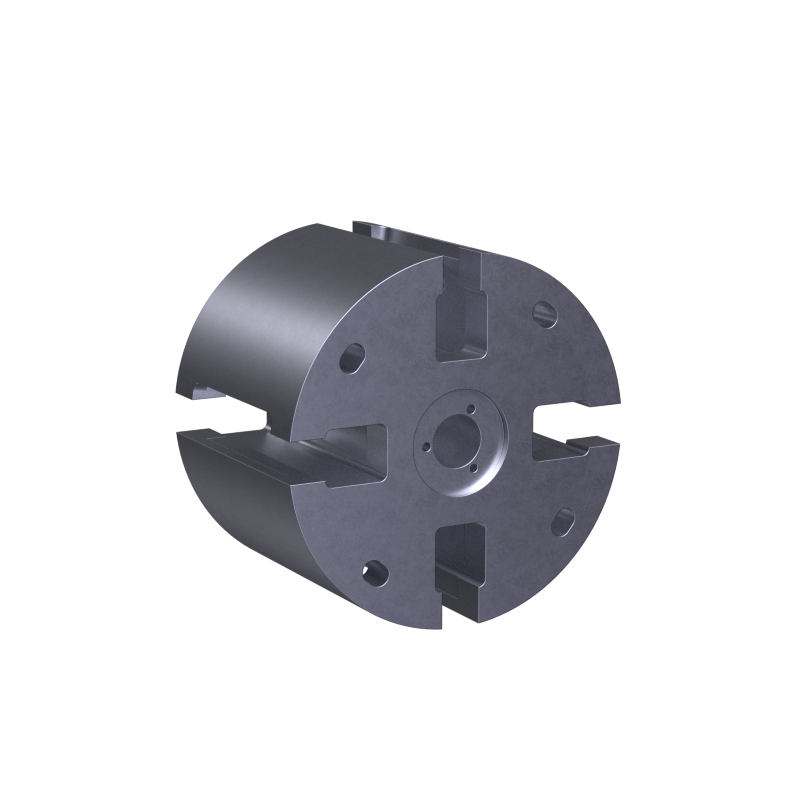

We are a long-running producer of air side componentry. One of the most successful projects has been the production and supply of rotor castings for air side fuel delivery. Aluminium die castings are produced in-house, before being subject to incredibly high tolerance CNC turning and milling processes. This is a perfect example of reasonably large volume components, which require absolute consistency of tolerance across each batch.