Our Power Generation Experience

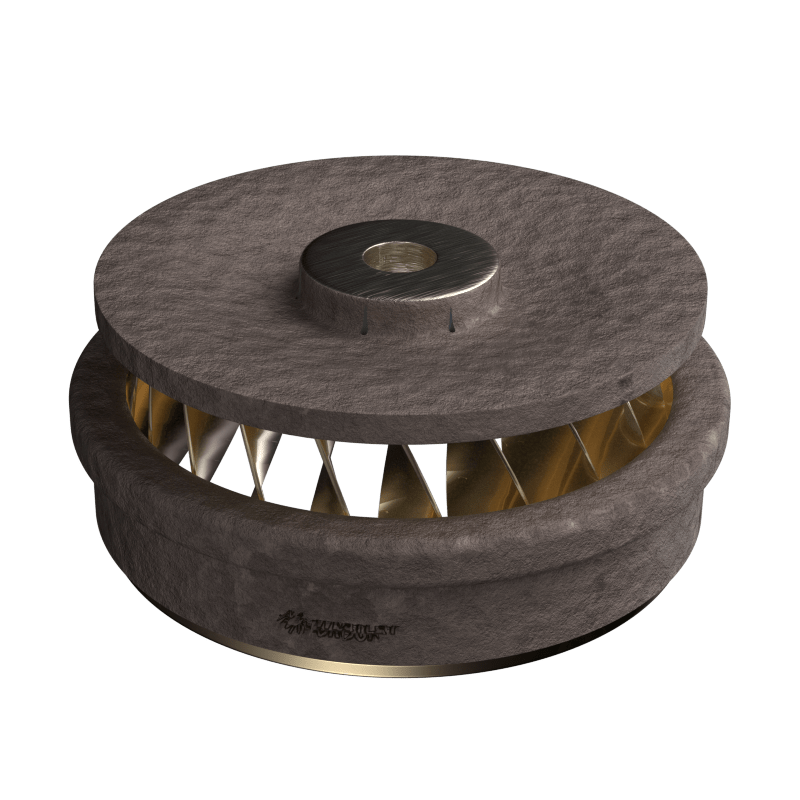

Having supplied complex hydro power components for many years, the group is undoubtedly one of the world’s most experienced foundries for highly cored impellers, turbines, runners and blades.

Our experience of tooling, sand casting, highly alloyed copper/nickel-based alloys, stringent NDT and capacity planning/management is trusted to deliver critical projects. When nickel aluminium bronze is the alloy of choice, oxide elimination is critical to produce defect-free components using our proprietorial pouring techniques. An example of this type of supply and programme management was in the production of hydro power blades to create and power the canoeing and water sport rapids for the recent summer Olympics.

The Group worked intrinsically with its customer to redesign a critical con rod bearing assembly for power transmission in safety critical pumps. Prior problems were eliminated by allowing us to manage and produce the entire production process of the split assemblies. Rather than purchase various parts from different suppliers, we sourced static and centrifugal parts from within our Group, before using newly invested CNC machining centres and CNC lathes. Tolerance is critical for the components to be assembled and press fitted correctly for exacting customer requirements. While painting and serialisation are also provided as part of the completely integrated supply.