Westley Group has a close affiliation with the UK’s naval and land based military programmes, not to mention other international military programmes. We have embedded security structures and data sharing mechanisms which mean we can operate in accordance with all international defence security protocols.

Our processes and procedures are supported by an embedded infrastructure which guarantees traceability, responsibility, attention to detail and robust certification and documentation adherence. Collectively, this means we are a trusted partner for many of the world’s leading blue water navies and land based military programmes. Underpinning our strategic role is the understanding and commitment to ensure that the military personnel we service are safe and protected by the components we manufacture to guarantee they support their mission critical status.

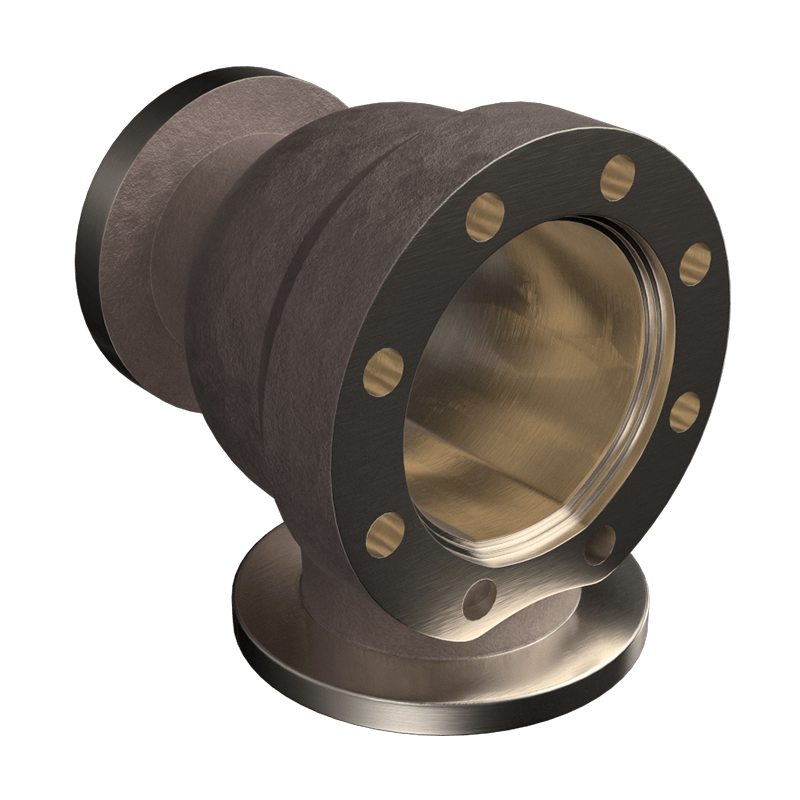

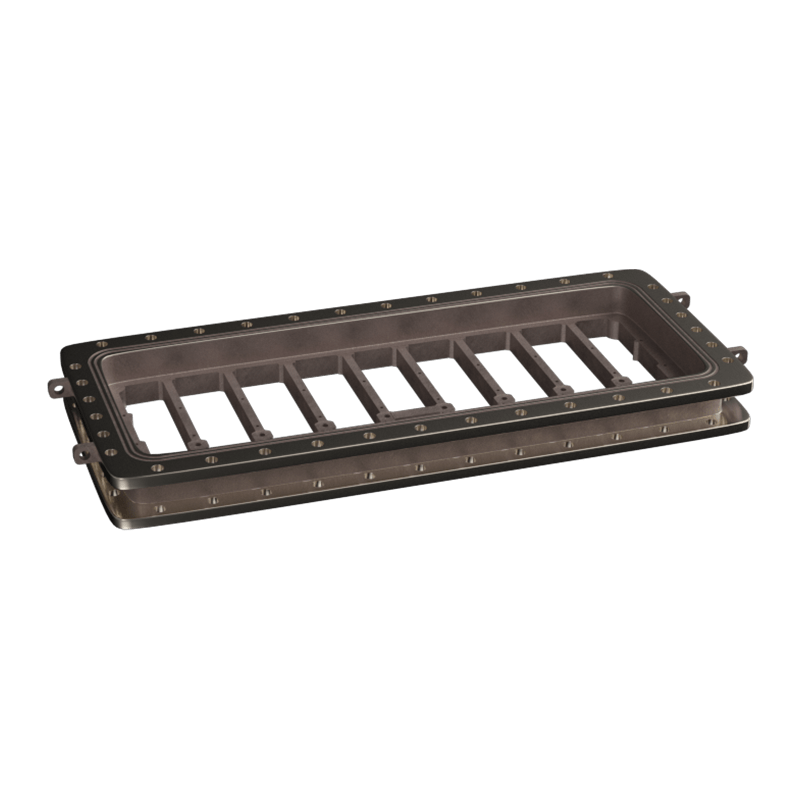

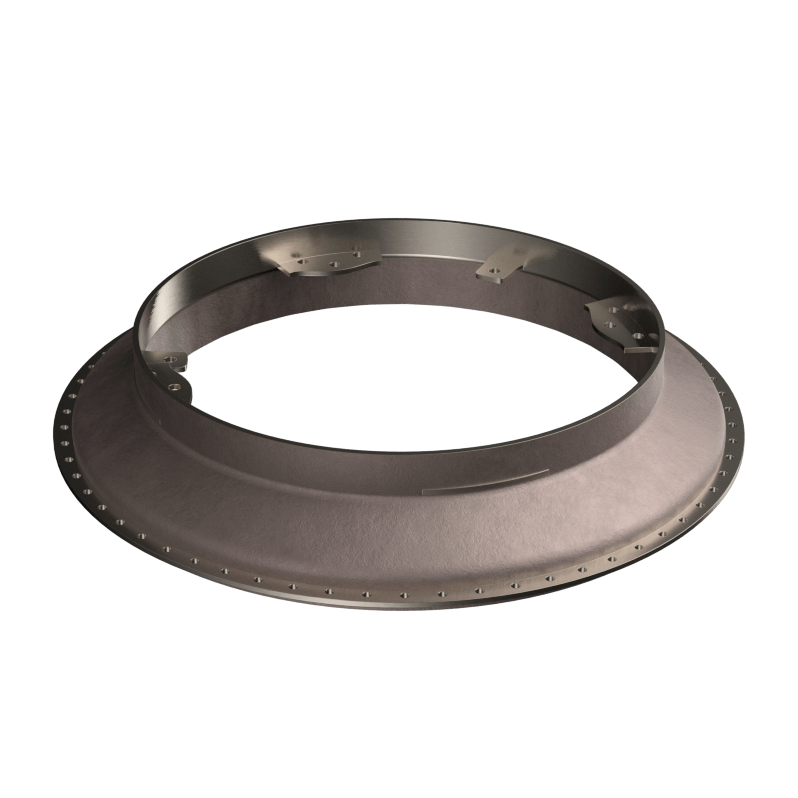

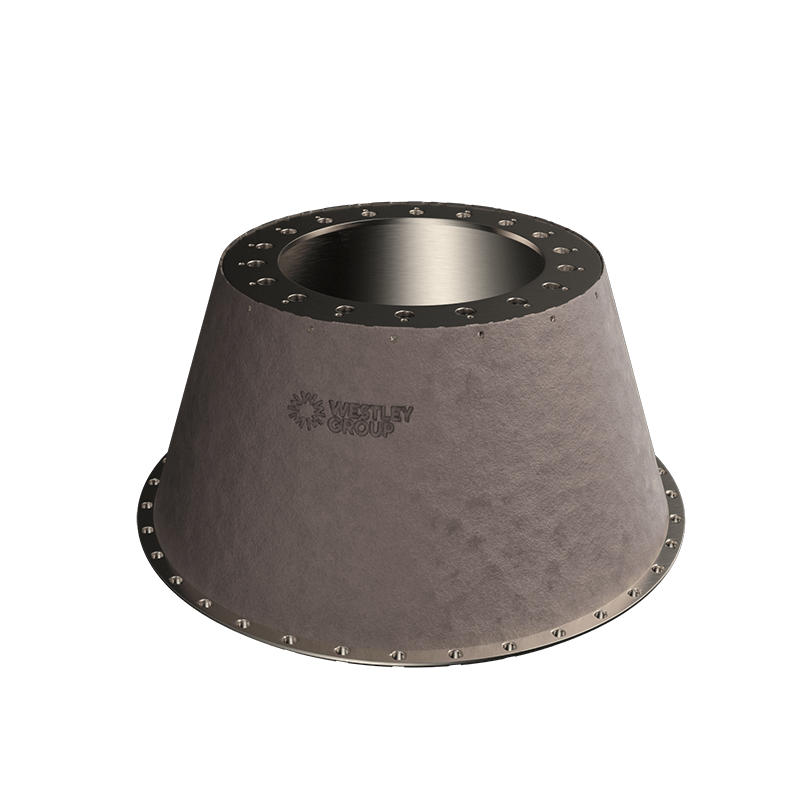

We manufacture all of the copper based castings which are used on our UK Submarine fleet, including primary heat exchange components, main condenser system castings, and complex submarine propulsor components; to name but a few. Components are often produced to net shapes using static or centrifugal casting processes, supported by our proprietary casting techniques which promote the manufacture of the highest integrity and structurally sound cast components.

Other notable examples include propeller tail shaft liners for many of the World’s navies in copper and nickel based alloys, our own designed and branded products for fire-fighting equipment for the UK’s naval surface ship programmes, and various defence standard aluminium alloy components with complex geometrical requirements for land based vehicles.