Acquisition of Meighs Castings Ltd, Stoke on Trent

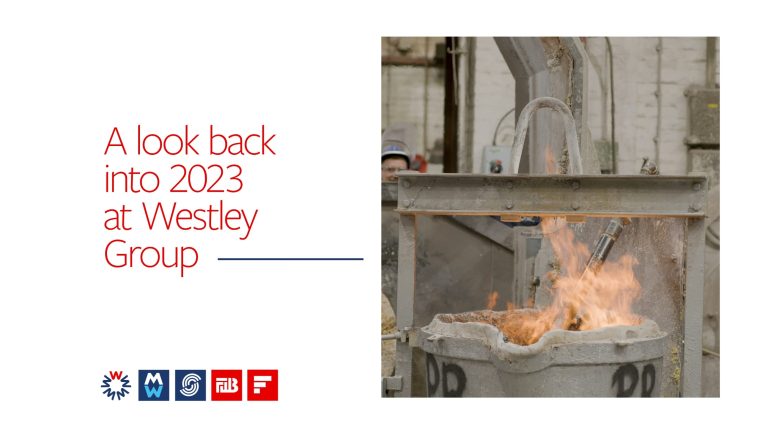

Westley Group is pleased to announce the acquisition of Meighs Castings Ltd, Stoke-on-Trent, United Kingdom.

Meighs Castings has a heritage very similar in nature to Westleys and Spunalloys, which are at the cornerstone of Westley Group operations. All three of these manufacturing divisions specialise in the supply of high integrity components that are machined and assembled for complex and demanding supply chains.

Westley Group has existing, extensive static casting operations in the Stoke-on-Trent area, however it is expected that it will be necessary to run both Meighs and the existing operations from their respective sites for the foreseeable future. There is deep recognition that the success of this acquisition requires the full support of the respective customers and partners of both Meighs and other Westley Group companies and that to facilitate this it must be ensured that all service levels are maintained and improved and that the commercial parameters are maintained so that the customers achieve the same level of competitive supply. To this end we will be consulting and working closely with our customers to ensure that we set up secure and transparent operating models going forwards.

Rob Salisbury (Westley Group Commercial & Development Director) commenting on the acquisition stated that “the amalgamation of Meighs into the Westley Group existing operation creates one of the most capable and well-resourced copper and nickel based cast and forging component suppliers in the UK, Europe and possibly the World. Our ability to offer complete DFM and complex build to print packages is industry leading”.

Further information should be sought from existing contacts where we will be pleased to provide more information.

MEIGHS CASTINGS LTD

Overview

At Meighs Castings we are recognised worldwide for our technical ability and metallurgical knowledge. We can offer advice to our customers in selecting the ideal alloy for heat, wear and corrosive environments. We are able to leverage both conventional processes and our own proprietary HPLT casting processes to minimise turbulence during pouring and produce sand castings of the highest integrity. We continually refine alloys and techniques to provide innovative metals solutions for customers with the most demanding corrosive applications.

Why not call us on +44 (0)1782 844055 to discuss your component needs?

Processes and Capabilities

Our on-site engineering staff work closely with our customers.

Melt and Pour Capacities

Speciality Processes

Materials

We routinely pour a broad range of ferrous and non-ferrous alloys

Materials Testing

-

MEIGHS CASTINGS LTD

Campbell Rd.

Stoke on Trent ST4 4ER, England

Tel: +44(0)1782 844 055

Fax: +44(0)1782 744 476