A highly skilled process

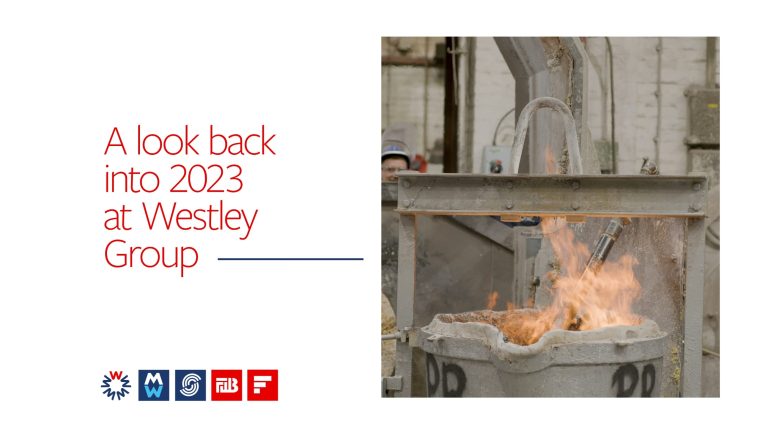

A successful sand casting process requires high levels of skill, experience, and learned operating procedures, which are all supported by highly invested capital equipment. The process uses bonded sand to create very near nett shape components with intricate detailing and passageways from a few kilograms to many tonnes in weight. Our customers rely on us because of our ability to meet incredibly demanding acceptance criteria across all heat, wear, and corrosion-resistant alloys with flexible capacity.

With decades of experience and embedded processes, Westley Group is supported by casting simulation software engineers and gifted technicians, delivering single units and high-volume manufacture.

One of our most experienced engineers is our Foundry Director, Terry King. Terry has worked in various foundry roles for over 40 years and is vastly experienced in the intricacies of all non-ferrous metals with their interrelationship with manufacturing techniques and component geometry.

Terry oversees all technical development across all the Group’s foundries but specifically the two static centres of excellence. Terry commented “the most difficult challenge in the foundry industry over the last 15 years has been the ever-demanding acceptance standards imposed down the supply chain. We have had to accept and embrace the changes, and find techniques and process controls to continually evolve our capability to remain at the very top of the industry. Without doing this we would not be trusted to deliver some of the incredibly difficult components we are relied upon to deliver”.